راه حل های پیشرو و کیفیت تولید در کلاس جهانی

این شرکت آمادگی دارد که با کارفرمایان محترم همکاری اثربخشی را در زمینه ارائه خدمات اجرایی نظارت کارگاهی و مدیریت پیمان، بازرسی فنی و ایمنی در کازگاههای ساخت و نصب، مستند سازی پروژه های صنعتی از جمله صنایع نیروگاهی، نفت و گاز و پتروشیمی، هوا فضا، خودرو، دریایی، نظامی، راه آهن و تولید ارائه نماید.

خدمات قابل ارائه این شرکت شامل (و نه محدود به) بازنگری مستندات طراحی، تدوین رویه ها، کتابچه و برنامه های کیفیت، دستورالعمل های فنی و آموزشی، انجام امور بازرسی، نظارت و ممیزی کیفی عملیات اجرائی و ساخت و ضمن بهره برداری و تهیه گزارشات کارشناسی می باشد.

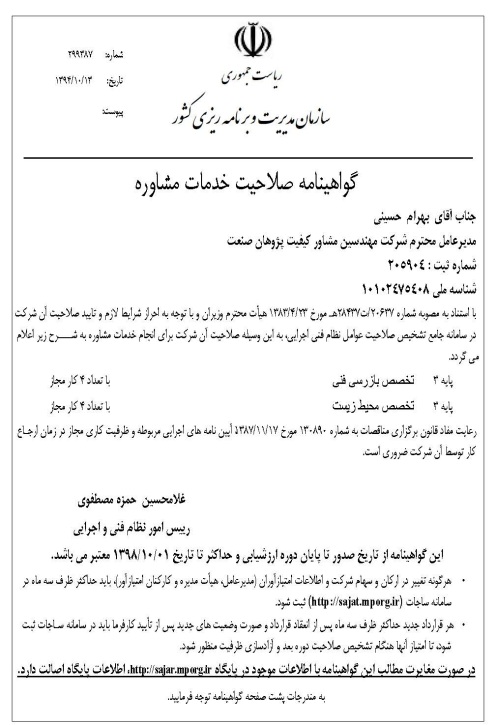

مهندسین مشاور کیفیت پژوهان صنعت IQS با بیش از دو دهه فعالیت در زمینه ارائه خدمات مشاوره، پیاده سازی، اجرایی و آموزشی در امور نظارت کارگاهی، کنترل و تضمین کیفیت، بازرسی فنی کالا و تجهیزات، ارائه آزمایشات غیر مخرب، بازرسی ایمنی و بهداشت، بازرسیهای حین سرویس و مدیریت یکپارچه دارائی ها... از جمله شرکتهای پیشرو در این حوزه میباشد.

به عنوان یکی از زبده ترین شرکتهای حاضر در زمینه ارائه خدمات مهندسی بازرسی فنی و آزمایش غیر مخرب (NDT)، آمادگی دارد تا کارفرمایان محترم را در دستیابی به نیازهای بازرسی حیاتی خود همراهی نماید.

مشاوره مهندسی، خدمات نظارت کارگاهی، مدیریت پیمان و بازرسی ایمنی و فنی

۱- تدوین و ارزیابی مدارک فنی و مهندسی طرح

۲- ارائه خدمات نظارت کارگاهی و کنترل کیفیت و بازرسی فنی

۳- ارزیابی عمر باقیمانده قطعات و تجهیزات صنعتی در حین کار، از طریق انجام بازرسی های بر مبنای ریسک Risk Based Inspection

۴- ارزیابی مواد و مصالح ساخت و بررسیهای در زمینه مکانیک شکست Failure Analysis

چه می توانیم پیشنهاد کنیم

خدمات ما

مشاوره سیستم های تضمین کیفیت Quality Assurance

۱- پیاده سازی و اجرای سیستم های مدیریت کیفیت تا مرحله اخذ گواهینامه

۲- انجام ممیزیهای دوره ای سازمانها و ارزیابی تامین کنندگان و سازندگان

۳- بازرسی جوش و کنترل کیفی عملیات در حین اجرا

۴- انجام آزمایشات کارگاهی و آزمایشگاهی جوش بروشهای مخرب و غیر مخرب

۵- آموزش و صدور گواهینامه های بازرسی جوش، کنترل کیفی و آزمایشات غیر مخرب

۶-ارائه سرویسهای بازرسی غیر مخرب پیشرفته (PAUT, TOFD, MFL…)

تدوین و اجرای سیستم کنترل و تضمین کیفیت در تمامی دیسیپلین های کاری پروژه های ساخت و نصب شامل کارهای بخش:

۱- سیویل از محوطه سازی تا اجرای فونداسیونهای صنعتی و نصب اسکلت فلزی

۲- نصب و راه اندازی تجهیزات الکتریکی برقی و ابزار دقیق شامل کابل کشی، نصب ترانس و تابلو، اطاق کنترل و ....

۳- نصب و راه اندازی تجهیزات مکانیکی ثابت و دوار

۴- انجام کنترل کیفیت در فرآیندهای ساخت شامل؛ ماشینکاری، عملیات حرارتی، رنگ آمیزی، عایقکاری، کنترل ابعادی، ....

تدوین و بازنگری برنامه زمان بندی پروژه در بخش های مستقل E-P-C بر مبنای قرارداد

۱- بررسی و تائید ضرایب وزنی پیشرفت پروژه و بودجه بندی

۲- تهیه و تائید گزارشات کنترل پروژه، تحلیل انحرافات برنامه ای و ارائه راهکار

۳- بررسی و تائید گزارشات دوره ای پیشرفت، بررسی و تائید کارکرد عوامل اجرائی

پروژه های در حال انجام

پروژه بازرسی ساخت و نصب اسکلت فلزی پروژه امیریه آمل

کارفرما: ارس دیبا

خدمات: نظارت کارگاهی

پروژه نظارت بر نصب و راه اندازی تجهیزات کارخانه کاغذسازی زنجان

کارفرما: راشا کاسپین ایرانیان

خدمات: نظارت کارگاهی

پروژه بازرسی ایستگاههای گاز استان زنجان

کارفرما: شرکت گاز زنجان

خدمات: بازرسی حین سرویس

اگر به راه حل صنعتی نیاز دارید ... ما برای شما در دسترس شما هستیم

لورم ایپسوم متن ساختگی با تولید سادگی نامفهوم از صنعت چاپ و با استفاده از طراحان گرافیک است.

چرا IQS

خدمات بازرسی شایستگی محوری ماست

باور داریم که آمیخته تخصص و تجربیات عملی ما در حوزه خدمات سیستمهای مدیریت، بازرسی و NDT ، برای مشتریان منجر به خلق ارزش شده و مزایای رقابتی بسیاری ایجاد نموده است.

ما ارائه خدمات تخصصی مبتنی بر نتایج را به شما پیشنهاد می کنیم

افتخار ماست که برای بیش از دو دهه، در تدوین و پیاده سازی علمی و استانداردهای بازرسی فنی و NDT در صنایع ملی و چند رشته ای نقش آفرینی نمودهایم.

IQS با تکیه بر تجربیات گوناگون مدیران خود سطح جدیدی از عملکرد، بهره وری و قابلیت پیش بینی را برای کارفرمایان ارائه نموده است. افتخار داریم که دانش، تجربه و تلاش تخصصی IQS در هر راه حلی که ارائه می دهیم برای مشتریان مان مزایای رقابتی و تفاوت ایجاد نموده است.

نوآوری برای مشتری

خوشحالیم که به طور پیوسته در مسیر به کارگیری دانش روزآمد و فناوری پیشرفته ای بازرسی که مشتریان به آن نیاز دارند گام برداشته و در حال سرمایه گذاری هستیم. فرهنگ نوآوری مشتری محور ما بیش از هر زمان دیگری مهم است، زیرا سرعت کسب و کار در کلیه صنایعی که ما به آنها خدمت ارائه میکنیم شتاب یافته است.

راه حل های پیشرو و کیفیت تولید در کلاس جهانی

ما طیف گسترده ای از خدمات و راه حل های یکپارچه بازرسی و NDT را از نیازسنجی مشتری تا تحویل و تحلیل نتایج بازرسی را ارائه می دهیم.

باور داریم که اقدامات کاربردی ما، یکپارچه سازی خدمات، محصولات و دارائی ها و نیازهای منحصر به فرد مشتریان مان را تامین خواهد نمود.

راه حلهای علمی و مهندسی شده ما میتواند با سامان بخشی فعالیتهای کنترل کیفیت همسو با استراتژیها و اقدامات تجاری کلان مشتریان و بنگاهها بازگشت سرمایه طرحها را در کوتاه مدت تضمین کند.

در IQS، نوآوری با ارتقا معیارهای کیفی طراحی و مهندسی آغاز می شود و با تولید و تضمین کیفیت خود ادامه می یابد. جاری سازی فرهنگ نوآوری از طراحی تا تحویل تضمین می کند که مشتریان ما در هر مرحله از راه از کیفیت بالا و پیشرفت های جدید بهره مند شوند.